This is known as a dry type or direct expansion evaporator. Enhancements on the outside and the inside produce exceptional performance and efficiency. Shell and tube evaporator design.

Shell And Tube Evaporator Design, O r g Page 100 considering tube length thickness and tube patterns Triangular or Rectangular Pattern by doing so the overall heat transfer Pressure drop and cost are studied and the allowable design is chosen from thermal design point of. Shell And Tube Evaporators. Design Alfa Lavals new DM shell-and-tube evaporator series guarantees maximum efficiency low cost and top performance. Design Of A Shell And Tube Evaporatorcondenser - posted in Student.

Shell And Tube Type Heat Exchanger Explained Savree From savree.com

Shell And Tube Type Heat Exchanger Explained Savree From savree.com

Shell Tube Evaporator DCON. 600 bar FUNKE shell-and-tube heat exchangers Straight tube U-shaped tube safety heat exchangers in all common. The design of the evaporator is a fixed tube counter flow shell tube heat exchanger as shown in Figure 2. A j e r.

Short-tube vertical evaporators consist of a short tube bundle about 1 to 3 m in length enclosed in a cylindrical shell.

Read another article:

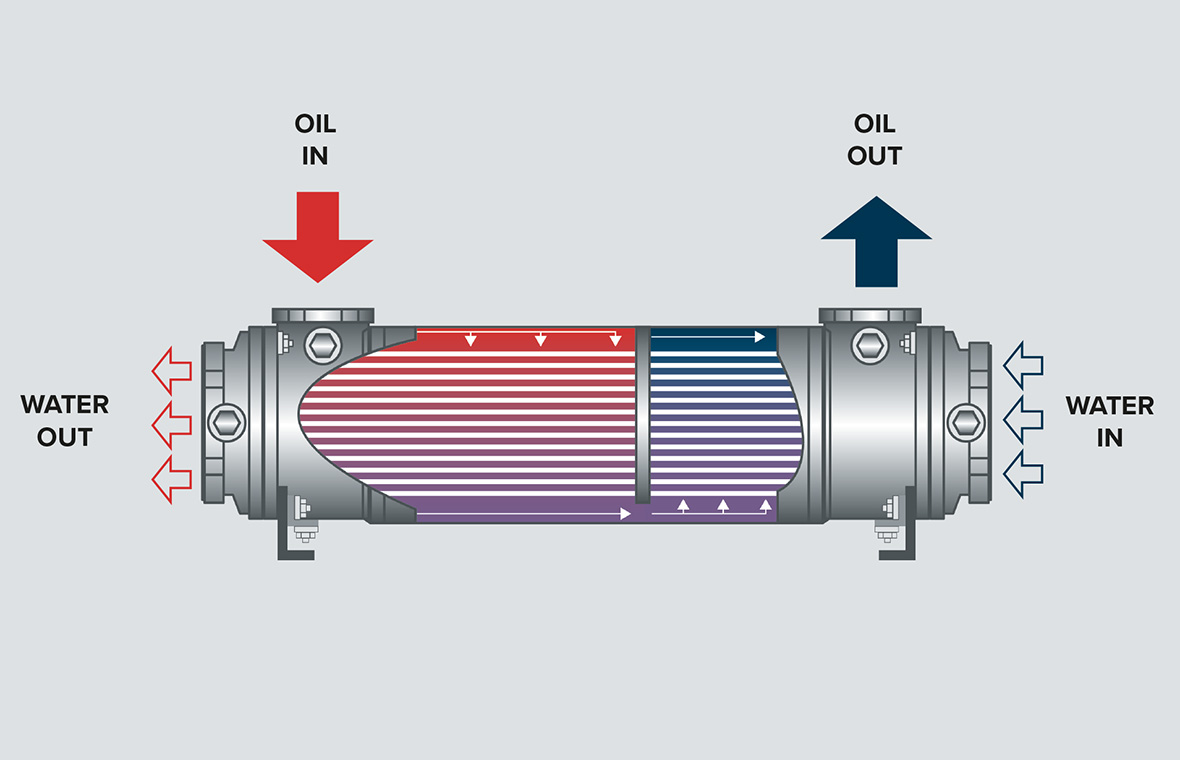

Shell Tube Evaporator DCON. The design of shell and tube heat exchanger using Kern method for water and steam combination is validated by well-known Dittus-Boelter equation of turbulent flow inside tube. A shell and tube heat exchanger is divided into two compartments. 1 refrigerant boiling in the tubes chilling in the shell the liquid flowing across the tube bundle with its direction repeatedly reversed by baffles and 2. Evaporator is sometimes known as standard evaporator.

Source: summaryplanet.com

Source: summaryplanet.com

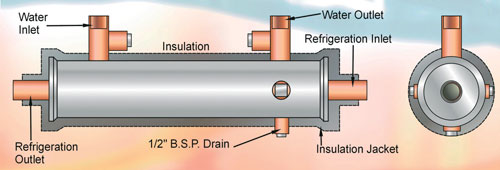

The water enters the side of the shell at one end and leaves the side of the shell at the other. 1 refrigerant boiling in the tubes chilling in the shell the liquid flowing across the tube bundle with its direction repeatedly reversed by baffles and 2. Now I want to size the shell and tube heat exchanger which is the main component used for heating brine with superheated steam in order to be able to calculate the pressure losses in the. Pressure gauge - Mohamed Mosaad Sight glass - MeysamG Screws Nuts - Mikołaj Chr. Evaporators And Condensers.

Source: pinterest.com

Source: pinterest.com

Design Alfa Lavals new DM shell-and-tube evaporator series guarantees maximum efficiency low cost and top performance. Pressure gauge - Mohamed Mosaad Sight glass - MeysamG Screws Nuts - Mikołaj Chr. ServiceFirst offers ACME DXT shell and tube evaporators condensers and marine condensers. Basic technical data depending on design Performance 1 KW up to 30 MW Transfer surface 011 m² up to 2000 m² Shell diameter 60 mm up to 2000 mm Operating temperature -20C up to 500C Operating pressure max. Heat Exchangers Heat Exchanger Heat Manufacturing.

Source: enggcyclopedia.com

Source: enggcyclopedia.com

Some of the major forms of construction include. We offer a premium range of shell and tube type chiller. The tube and steam on shell side. It composed of heat transfer rate and total pumping power. Shell Tube Heat Exchanger Equations And Calculations Enggcyclopedia.

Source: ipieca.org

Source: ipieca.org

The design of the evaporator is a fixed tube counter flow shell tube heat exchanger as shown in Figure 2. Shell Tube Evaporator DCON. Shell and tube chillers are supplied with screwed or flanged water connections. Basic technical data depending on design Performance 1 KW up to 30 MW Transfer surface 011 m² up to 2000 m² Shell diameter 60 mm up to 2000 mm Operating temperature -20C up to 500C Operating pressure max. Heat Exchangers Ipieca.

Source: kelvion.com

Source: kelvion.com

Dryplus-3 shell tube evaporators Excellence and flexibility in performance Performances and features Perfection in construction Integrate water tank solutions Quality and approvals Auxiliary connections Supports 18-47 kW 56-95 kW 120-165 kW 200-240 kW 300-345 kW 385-450 kW 505-570 kW 660-770 kW 915-1000 kW 1100-1500 kW COMPACT 160-210 kW COMPACT 235-275. It composed of heat transfer rate and total pumping power. We use 3D models animations and real li. Constructal design of shell-and-tube evaporator is conducted. Shell Tube Single Comfin Heat Exchanger Kelvion.

Source: hstarschiller.com

Source: hstarschiller.com

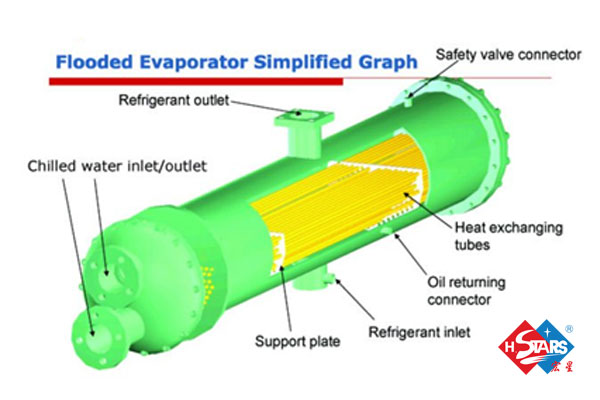

A shell and tube heat exchanger is used as a condenser and an evaporator in this theoretical study. O r g Page 100 considering tube length thickness and tube patterns Triangular or Rectangular Pattern by doing so the overall heat transfer Pressure drop and cost are studied and the allowable design is chosen from thermal design point of. Condensation and evaporation were occurred in the shell side while the water was flowing in the tube side of heat exchanger. The design of shell and tube heat exchanger using Kern method for water and steam combination is validated by well-known Dittus-Boelter equation of turbulent flow inside tube. Best Low Temperature Shell And Tube Flooded Type Evaporator Low Temperature Shell And Tube Flooded Type Evaporator Suppliers Manufacturers.

Source: pmarpl.com.au

Source: pmarpl.com.au

It is also a type of shell and tube chiller where the water runs through the tubes and the refrigerant flows over the outside of the tubes within a closed shell. Heat exchangers require approved welding procedures and our ASME certified welders combined with our design and project team are experienced to be able to meet the strict requirements of industrial heat exchangers. Heat exchanger design project in university —- Credits. The tube and steam on shell side. Shell And Tube Heat Exchanger.

Source: enggcyclopedia.com

Source: enggcyclopedia.com

Now I want to size the shell and tube heat exchanger which is the main component used for heating brine with superheated steam in order to be able to calculate the pressure losses in the. O r g Page 100 considering tube length thickness and tube patterns Triangular or Rectangular Pattern by doing so the overall heat transfer Pressure drop and cost are studied and the allowable design is chosen from thermal design point of. In this type of evaporator the liquid flows as a thin film on the walls of long from 12 to 30 feet in length and vertical heated tube. In this video we look inside the evaporator of a chiller to learn how it works and how it operates in a HVAC system. Shell Tube Heat Exchanger Pressure Drop Enggcyclopedia.

Source: thomasnet.com

Source: thomasnet.com

DXTDXC Evaporators ACME DXTDXC evaporators are designed specifically for refrigerant evaporation. FEV HP Series Applications Flooded evaporators for air condition-ing and process cooling applications where the primary driving force is energy efficiency improvement es-pecially at part load conditions. Dryplus-3 shell tube evaporators Excellence and flexibility in performance Performances and features Perfection in construction Integrate water tank solutions Quality and approvals Auxiliary connections Supports 18-47 kW 56-95 kW 120-165 kW 200-240 kW 300-345 kW 385-450 kW 505-570 kW 660-770 kW 915-1000 kW 1100-1500 kW COMPACT 160-210 kW COMPACT 235-275. Shell and tube chillers are supplied with screwed or flanged water connections. All About Shell And Tube Heat Exchangers What You Need To Know.

Source: enggcyclopedia.com

Source: enggcyclopedia.com

A shell and tube heat exchanger is used as a condenser and an evaporator in this theoretical study. Shell-and-tube dry expansion evaporator Alfa Laval DM Benefits A unique patented refrigerant distribution system which has been optimized for R407F and R134a. Heat exchangers require approved welding procedures and our ASME certified welders combined with our design and project team are experienced to be able to meet the strict requirements of industrial heat exchangers. Enhancements on the outside and the inside produce exceptional performance and efficiency. Shell Tube Heat Exchanger Diagram Enggcyclopedia.

Source: thomasnet.com

Source: thomasnet.com

Now I want to size the shell and tube heat exchanger which is the main component used for heating brine with superheated steam in order to be able to calculate the pressure losses in the. Tube length usually varies from 20 to 65 ft. Both rising film and falling types are used. Shell and tube Evaporator 3D CAD Model Library GrabCAD. All About Shell And Tube Heat Exchangers What You Need To Know.

Source: acr-news.com

Source: acr-news.com

This is called calandria. FEV HP Series Applications Flooded evaporators for air condition-ing and process cooling applications where the primary driving force is energy efficiency improvement es-pecially at part load conditions. A comparable shell-and-tube evaporator thereby minimizing the amount of ammonia in a process chiller. Shell and tube Evaporator 3D CAD Model Library GrabCAD. Masterclass Shell Tube Evaporators Part 15.

Source: pinterest.com

Source: pinterest.com

These are easy to maintain hence they are very widely used in medium to large capacity refrigeration systems. Very efficient single pass and counter-. Mainly in the flooded chiller approximately 50 to 75 of the tubes are immersed in liquid refrigerant and the space above provides an allowance for the vapor generated through evaporation of the liquid below. DXTDXC Evaporators ACME DXTDXC evaporators are designed specifically for refrigerant evaporation. Liquid To Liquid Heat Exchangers Hvac Diy Heat Exchanger Heat.

Source: pinterest.com

Source: pinterest.com

Mainly in the flooded chiller approximately 50 to 75 of the tubes are immersed in liquid refrigerant and the space above provides an allowance for the vapor generated through evaporation of the liquid below. This is known as a dry type or direct expansion evaporator. Also plate evaporators require less refrigerant charge vs. These are easy to maintain hence they are very widely used in medium to large capacity refrigeration systems. What Is A Shell And Tube Heat Exchanger Used For Heat Exchanger Heat Air Cooling System.

Source: hstarschiller.com

Source: hstarschiller.com

600 bar FUNKE shell-and-tube heat exchangers Straight tube U-shaped tube safety heat exchangers in all common. Both rising film and falling types are used. Constructal design of shell-and-tube evaporator is conducted. This is called calandria. Best Industrial Flooded Shell And Tube Heat Exchanger Industrial Flooded Shell And Tube Heat Exchanger Suppliers Manufacturers.