What actually is the bentonite slurry. Bentonite content of 6 percent by weight should meet. Bentonite slurry mix design.

Bentonite Slurry Mix Design, ρ m 100 c w ρ s 100 - c w ρ l 1. The mix resulted in 9 percent cementitious materials a watercementitious material ratio WC of 034 and 09 percent bentonite. The final mix design consisted of 180 pounds of cement 51 pounds of flyash 2542 pounds of soil dry weight 50 gallons of bentonite slurry and 312 gallons of reservoir water. The mix design should always - especially in unknown conditions - be determined by suitability tests prior to the start of.

Barrier Walls Pollution Prevention Climate Policy Watcher From climate-policy-watcher.org

Barrier Walls Pollution Prevention Climate Policy Watcher From climate-policy-watcher.org

Low hydraulic conductivity workability and physical stability commonly used as the main acceptance criteria for conventional soil-bentonite slurry mixes are no longer the only governing parameters. But when it is dry-blended with cement and then added to mix water it does not hydrate completely Hydration inhibited by Ca2 ions in the slurry. When bentonite is mixed with water it form a gel under static conditions but when disturbed or when distressed it regains its fluidity. Bentonite cement earthfill sand unpermeable layer.

Bentonite slurry mixture may begin.

Read another article:

Bentonite content of 6 percent by weight should meet. Tolunay-Wong hydrated the bentonite slurry for 4 hours prior to adding it to the soil or to the soil and dry bentonite mixtures. The design mix stage too. A slurry is a thin sloppy mud or cement or in extended use any fluid mixture of a pulverized solid with water often used as a convenient way of handling solids in bulk. Soil-bentonite containment contaminant compatibility slurry cutoff wall laboratory testing oil-products design mix.

Source: climate-policy-watcher.org

Source: climate-policy-watcher.org

A composite soil sample will then be mixed with bentonite in various ratios to determine the most appropriate design for a SB backfill mixture to be used. C w concentration of solids by weight in the slurry. The bentonite slurry was mixed in a Hobart mixer. Compare to dry-blended when mixed with mix water bentonite will hydrate totally in 30 min properties of bentonite are boosted because it absorbs an important volume of water. Barrier Walls Pollution Prevention Climate Policy Watcher.

Source: researchgate.net

Source: researchgate.net

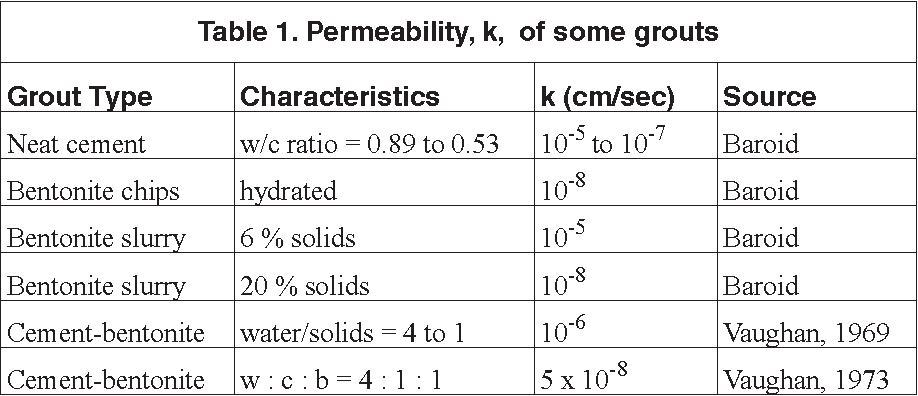

If the concentration Cs is expressed as kilograms of bentonite per cubic meter of final slurry then the formula becomes. Bentonite CB wall is a variation of the process in which cement is added to the slurry so that after the excavation process the slurry sets up without a separate backfilling operation. Technological criteria are required to design the bentonite-cement slurry composition. The design mix stage too. Concrete Mix Design Used For Laboratory Tests Download Table.

Source: geo-solutions.com

Source: geo-solutions.com

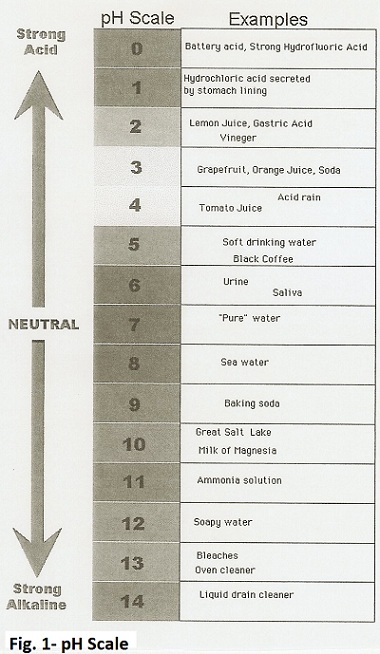

Quality control of the slurry is via batching records and tests carried out to evaluate fluid properties primarily density pH and viscosity for mix consistency. Mixing of the constituents generally proceeded along the trench in a linear fashion. The design of the slurry mix is undertaken in the laboratory to test the interaction of the mix-water cement bentonite and other cement replacement materials. Ps pw 1 C CGp 1 where pw is the specific gravity of the mixing water assumed to be 10 and Gp is the grain specific gravity of the bentonite powder used to prepare the slurry. Soil Bentonite Slurry Walls Geo Solutions Soil And Groundwater Problems Solved.

Source: keller.com.au

Source: keller.com.au

C w concentration of solids by weight in the slurry. The design of the slurry mix is undertaken in the laboratory to test the interaction of the mix-water cement bentonite and other cement replacement materials. ρ s density of the solids lbft 3 kgm 3. A slurry is a thin sloppy mud or cement or in extended use any fluid mixture of a pulverized solid with water often used as a convenient way of handling solids in bulk. Slurry Cut Off Walls Keller Australia.

Source: geo-solutions.com

Source: geo-solutions.com

Slurry is a mixture of a solid and a liquid. Cement plus Bentonite Selected for reducing slurry density and increasing slurry volume Normal bentonite additions range from 1 to 12 percent by weight of cement bwoc For every 1 bentonite bwoc added the water content must be increased 065 gallons assumes dry blending Bentonite reduces resistance of cement to. Mix Design Rules In order to keep field procedures simple the emphasis should be on controlling the water-cement ratio. The bentonite slurry was mixed for a period of three minutes. Soil Bentonite Slurry Walls Geo Solutions Soil And Groundwater Problems Solved.

Source: researchgate.net

Source: researchgate.net

What actually is the bentonite slurry. ρ m density of slurry lbft 3 kgm 3. But when it is dry-blended with cement and then added to mix water it does not hydrate completely Hydration inhibited by Ca2 ions in the slurry. The density of a slurry can be calculated as. Blend Mix Proportions And Blend Slurry Properties Download Table.

Source: slideplayer.com

Source: slideplayer.com

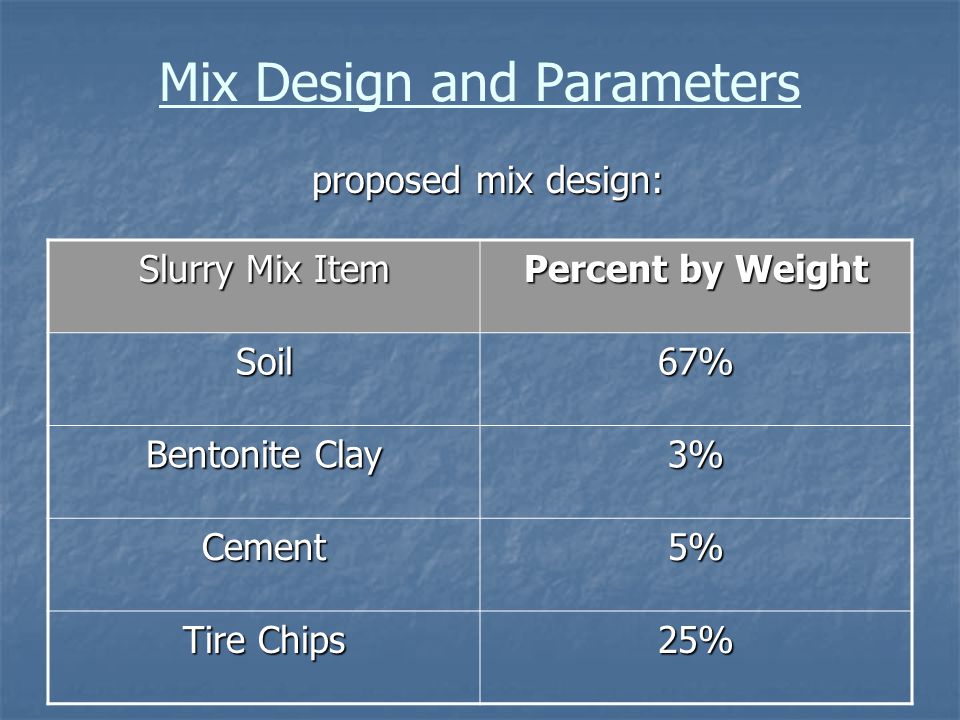

Cement plus Bentonite Selected for reducing slurry density and increasing slurry volume Normal bentonite additions range from 1 to 12 percent by weight of cement bwoc For every 1 bentonite bwoc added the water content must be increased 065 gallons assumes dry blending Bentonite reduces resistance of cement to. Source water was poured into the mixer and the mixing blade was turned on then bentonite was added. 6 DESIGN MONITORING AND WALL TESTING 61 Mix Design The main objectives of the mix design were. A composite soil sample will then be mixed with bentonite in various ratios to determine the most appropriate design for a SB backfill mixture to be used. The Feasibility Constructability And Efficacy Of Tire Derived Aggregate As A Component In Slurry Cutoff Walls Ppt Video Online Download.

Source: structville.com

Source: structville.com

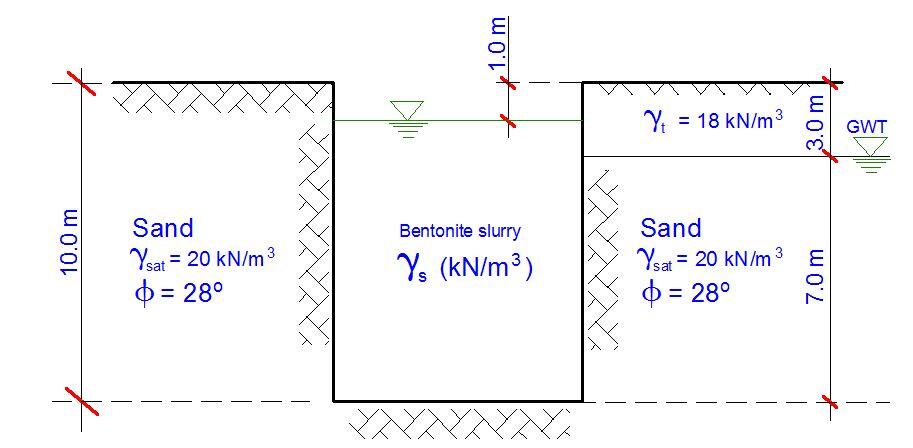

The most commonly employed slurry wall is known as a soil-bentonite cutoff wall and is composed of a backfill mixture of soil bentonite and water. Complete hydration is generally defined as the point when the slurry has reached a stable filter loss and viscosity. Compatibility of the soil-bentonite slurry mix with the ground waterliquid is as important and should be considered a major factor in the soil-bentonite slurry mix design. A composite soil sample will then be mixed with bentonite in various ratios to determine the most appropriate design for a SB backfill mixture to be used. Design Of Slurry Cut Off Walls Slurry Trenches Structville.

Source: simemug.com

Source: simemug.com

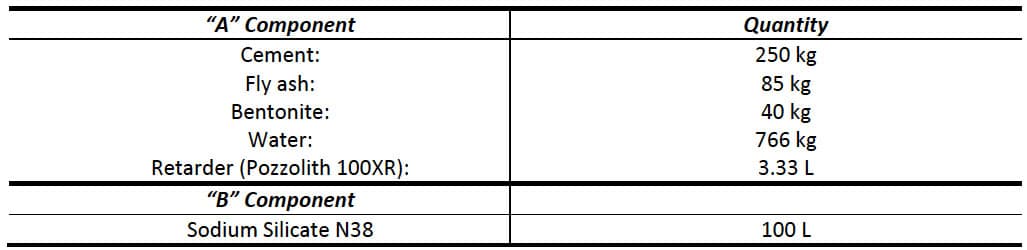

Complete hydration is generally defined as the point when the slurry has reached a stable filter loss and viscosity. The density of a slurry can be calculated as. Source water was poured into the mixer and the mixing blade was turned on then bentonite was added. Bentonite slurry mixture may begin. Performance Benefits Of Colloidally Mixed Two Component Grouts Simem Underground.

Source: geo-solutions.com

Source: geo-solutions.com

Low hydraulic conductivity workability and physical stability commonly used as the main acceptance criteria for conventional soil-bentonite slurry mixes are no longer the only governing parameters. Low hydraulic conductivity workability and physical stability commonly used as the main acceptance criteria for conventional soil-bentonite slurry mixes are no longer the only governing parameters. Proportionally and sequentially adding the cement bentonite and sodium carbonate into the stirring tank. 1200 kgm³ slurry Bentonite 30 50 kgm³ slurry 15 30 kgm³ slurry wc ratio 20 - 40 05 - 10 Wall characteristics typical predesign values Cut-off wall Retaining wall. Soil Cement Bentonite Slurry Walls Geo Solutions Soil And Groundwater Problems Solved.

Source: better-cementing-for-all.org

Source: better-cementing-for-all.org

Source water was poured into the mixer and the mixing blade was turned on then bentonite was added. A slurry is a thin sloppy mud or cement or in extended use any fluid mixture of a pulverized solid with water often used as a convenient way of handling solids in bulk. But when it is dry-blended with cement and then added to mix water it does not hydrate completely Hydration inhibited by Ca2 ions in the slurry. When water and cement are. All You Need To Know About Bentonite In Cement Slurries Better Well Cementing For All.

Source: clean-water-for-laymen.com

Source: clean-water-for-laymen.com

Starting the stirring tank. CB Design Mix At least two weeks prior to construction the Contractor shall submit proportions and properties of the proposed CB design mix including cement bentonite additives and water proportions. Compatibility of the soil-bentonite slurry mix with the ground waterliquid is as important and should be considered a major factor in the soil-bentonite slurry mix design. The design mix stage too. Mixing Bentonite Drilling Fluid.

Source: structville.com

Source: structville.com

What is the best procedure for mixing the slurry in the laboratory. Mixing of the constituents generally proceeded along the trench in a linear fashion. Cement plus Bentonite Selected for reducing slurry density and increasing slurry volume Normal bentonite additions range from 1 to 12 percent by weight of cement bwoc For every 1 bentonite bwoc added the water content must be increased 065 gallons assumes dry blending Bentonite reduces resistance of cement to. Compare to dry-blended when mixed with mix water bentonite will hydrate totally in 30 min properties of bentonite are boosted because it absorbs an important volume of water. Design Of Slurry Cut Off Walls Slurry Trenches Structville.

Source: semanticscholar.org

Source: semanticscholar.org

Of the free swell tests used in the selection of a ben-. It constitutes a mixture of bentonite slurry BS cement slurry CS and modifier M. A specific design mix methodology for evaluating the chemical compatibility of soil-bentonite slurry mixes with permeants is proposed. ρ m 100 c w ρ s 100 - c w ρ l 1. Pdf Cement Bentonite Grout Backfill For Borehole Instruments Semantic Scholar.

Source: semanticscholar.org

Source: semanticscholar.org

The preparation method comprises the following steps. The most commonly employed slurry wall is known as a soil-bentonite cutoff wall and is composed of a backfill mixture of soil bentonite and water. Technological criteria are required to design the bentonite-cement slurry composition. Bentonite is naturally found in form of sodium montmorillonite which exhibits thixotropic properties ie. Pdf Cement Bentonite Grout Backfill For Borehole Instruments Semantic Scholar.