The water is then returned to the plant 15 influent stream. For 6 mm bar spacing the open area is 60 3mm thick lamellas 50. Bar screen chamber design calculation.

Bar Screen Chamber Design Calculation, Step Screens are available with either 3mm or 2mm thick movable and 3mm or 2mm fixed lamellas. For example 2 wirecloth has a much higher basic capacity than 14 wirecloth. Spacing of 3mm is adopted between two adjacent bars. Basic capacities depend greatly on the design of the screen and most capacity formulas.

Wastewater Screening Classification Of Screens Complete List Wastewater Treatment Engineeringcivil Org From engineeringcivil.org

Wastewater Screening Classification Of Screens Complete List Wastewater Treatment Engineeringcivil Org From engineeringcivil.org

Design of the bar screen channel Approach Channel The cross section of the bar screen channel is determined from the continuity equation. Almost always used in new installations because of large number of advantages relative to other screens. For spacing of 20- 50 mm. Bar Screen.

To assist you in sizing and fitting your next wastewater screening design JWC has created a Quick Reference to help you measure and convert your specs for screens and components.

Read another article:

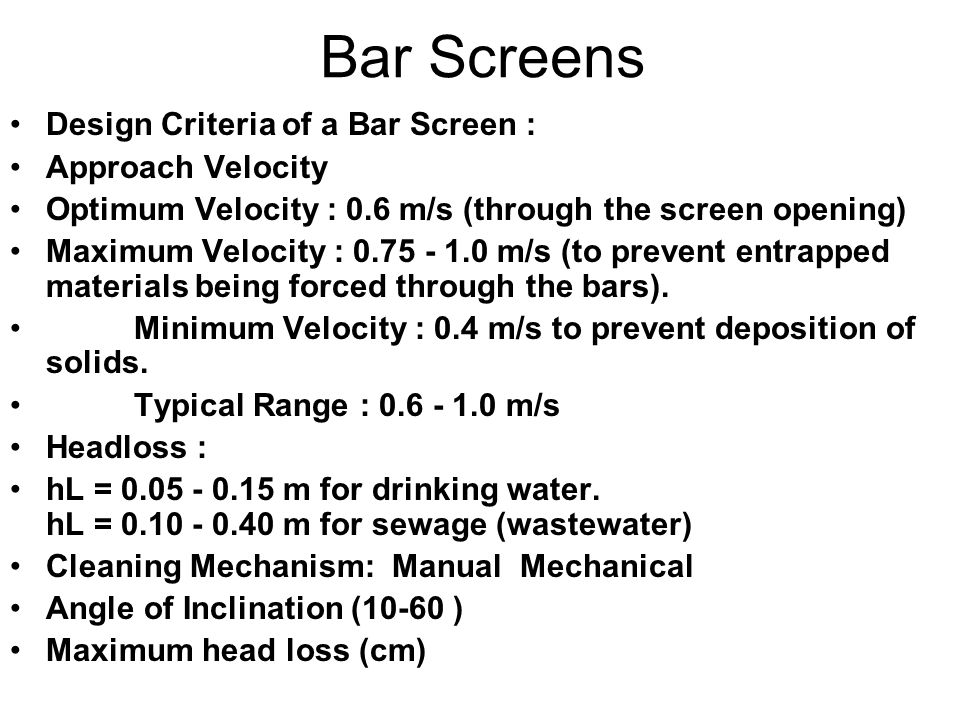

Screening removes objects such as rags paper plastics and metals to prevent damage and clogging of downstream equipment and pipingCleaning frequency depends on the characteristics of the wastewater entering a plant. Using a standard sizing formula 9 variables. Considerable attention should be given to the design of the screen channel to make ce rtain that conditions are as favorable as possible for efficient operation of the bar screen. Generally the quantity of screenings collected from a conventional bar screen is 16 approximately 30 to 45 liters of screenings per 1000 cubic meters 30-45 L1000 m3 or 4 to 6 17 cubic feet per million gallons 4-6. I Minimum bar size 10 mm x 50 mm ii Clear spacing between bars 15 mm to 75 mm iii Slope with horizontal- a Manually cleaned 45 to 60 b Mechanically cleaned 60 to 90 iv Minimum approach velocity 03 ms.

Source: researchgate.net

Source: researchgate.net

Peak design wet weather flow 0631 m3s Velocity through rack at peak wet weather flow 090 ms Velocity through rack at maximum design dry weather flow 06 ms θ 65 with a mechanical cleaning device Upstream depth of. The design of screen chamber is done by taking the standard dimensions of screen bars MS flats 25 X 3 mm. Discuss classification of screens and state application of each class. Generally the quantity of screenings collected from a conventional bar screen is 16 approximately 30 to 45 liters of screenings per 1000 cubic meters 30-45 L1000 m3 or 4 to 6 17 cubic feet per million gallons 4-6. Design Details Of The Grit Chamber Download Table.

Source: researchgate.net

Source: researchgate.net

That makes the step screen an excellent choice for applications where hydraulic. For the 2mm option the open surface area for a clean screen is 75 3mm thick lamellas 60. Width of screen chamber Wc is equal to Wc Width of screen Bars thickness 21 20 x 025 26 inch 217 ft Length of the screen Ls is equal to Depth of the screen chamber dc Ls Sinus on angle α Flow through screen Area available for flow x flow velocity Q A x Vc A Wc x dc Q Q max 15 cfs V c 15 fps. For 6 mm bar spacing the open area is 60 3mm thick lamellas 50. Design Details Of The Screen Chamber Download Table.

Source: youtube.com

Source: youtube.com

Design of the bar screen channel Approach Channel The cross section of the bar screen channel is determined from the continuity equation. The design of screen chamber is done by taking the standard dimensions of screen bars MS flats 25 X 3 mm. Provide net submerged area 077 m2. Unique factors of that application. Design Of Bar Screen Chamber Youtube.

V velocity before the screen in mps. CENTER FLOW SCREEN - Not your standard screen calculation. Number of bars in screenNumber of bars in screen chamberchamber clear spacing x n1 size of bar x n B WhereWhere N number of bars B width of screen chamber or channel Clear spacing and size of bars is expressed in m 17. Bar Screen Design Example A manual bar screen is to be used in an approach channel with a maximum velocity of 064 ms and a design flow of 300 Ls. 2.

Source: pinterest.com

Source: pinterest.com

It depends on the wirecloth opening size and design of the screen. Gross submerged area of the screen When n numbers of bars are used the ratio of opening to the gross width will be n130 n130 9 x n 077 for 20 to 30 number of bars Therefore gross submerged area of the screen 077 077 1 m2. Step Screens are available with either 3mm or 2mm thick movable and 3mm or 2mm fixed lamellas. Usually fine screens are preceded b a preliminary screening for the purpose of protection. Rubber Recycling Shredder Machine Machine Design Milling Machine.

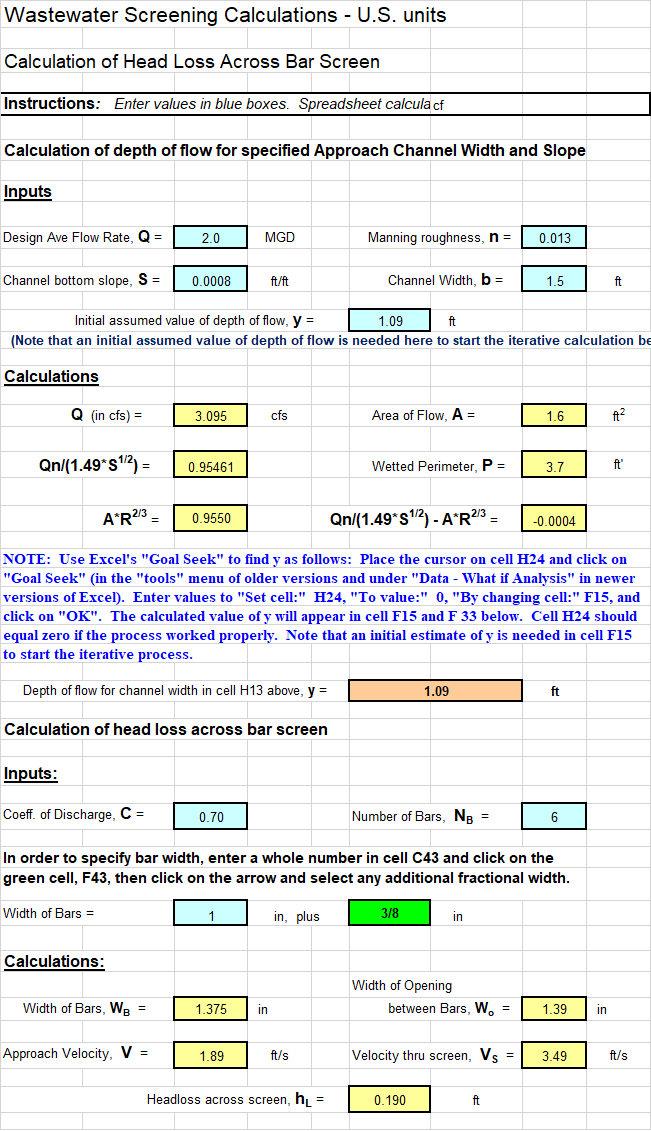

Source: engineeringexcelspreadsheets.com

Source: engineeringexcelspreadsheets.com

The bars are 10 mm thick and openings are 3 cm wide. Considerable attention should be given to the design of the screen channel to make ce rtain that conditions are as favorable as possible for efficient operation of the bar screen. Almost always used in new installations because of large number of advantages relative to other screens. The Effect of Screen Design on Capture Rate and Plant Maintenance Matt Bodwell. Bar Screen Archives Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheetslow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheets.

Source: nzdl.org

Source: nzdl.org

Basic capacities depend greatly on the design of the screen and most capacity formulas. A summary of the design information for bar screens or bar racks is given below. Bar Screen. The water is then returned to the plant 15 influent stream. 5 Design Formula For Screen.

Source: researchgate.net

Source: researchgate.net

The design of screen chamber is done by taking the standard dimensions of screen bars MS flats 25 X 3 mm. The different equipment calculations in our new quick reference guide include all of the specs necessary for installation. Basic capacities depend greatly on the design of the screen and most capacity formulas. For the 2mm option the open surface area for a clean screen is 75 3mm thick lamellas 60. Design Dimensions Of Inlet Chamber F Design Of Screening Screening Is Download Scientific Diagram.

Source: slideplayer.com

Source: slideplayer.com

Another formula often used to determine the head loss through a bar rack is Kirschmers equation. Generally the quantity of screenings collected from a conventional bar screen is 16 approximately 30 to 45 liters of screenings per 1000 cubic meters 30-45 L1000 m3 or 4 to 6 17 cubic feet per million gallons 4-6. Mechanical screens with bars inclined at an angle of 15 degrees from the vertical will be installed. The different equipment calculations in our new quick reference guide include all of the specs necessary for installation. Screening Jae K Jim Park Professor Ppt Video Online Download.

Source: slideplayer.com

Source: slideplayer.com

Considerable attention should be given to the design of the screen channel to make ce rtain that conditions are as favorable as possible for efficient operation of the bar screen. Spacing of 3mm is adopted between two adjacent bars. Bar Screen. Gross submerged area of the screen When n numbers of bars are used the ratio of opening to the gross width will be n130 n130 9 x n 077 for 20 to 30 number of bars Therefore gross submerged area of the screen 077 077 1 m2. Screening Definition Ppt Video Online Download.

Peak design wet weather flow 0631 m3s Velocity through rack at peak wet weather flow 090 ms Velocity through rack at maximum design dry weather flow 06 ms θ 65 with a mechanical cleaning device Upstream depth of. Bars set at 0 to 30 degrees from vertical. 1 Ventilation Capacity π 24 2 4 5 mH 2 3 timeshr 160 5652 m 3 min. The Effect of Screen Design on Capture Rate and Plant Maintenance Matt Bodwell. 2.

Source: academia.edu

Source: academia.edu

Design of Municipal Wastewater Treatment Plants WEF MOP 8 Fourth Edition 1998. A summary of the design information for bar screens or bar racks is given below. The water is then returned to the plant 15 influent stream. The angle to which the screen bars are inclines is 450The side view of screen and grit chamber is shown in figure 2 Figure 2The side view of the Screen Grit Chamber. Doc Design A Coarse Screen And Calculate The Headless Through The Rack Royal Eagle Academia Edu.

Source: pinterest.com

Source: pinterest.com

Bars set at 0 to 30 degrees from vertical. CENTER FLOW SCREEN - Not your standard screen calculation. Number of bars in screenNumber of bars in screen chamberchamber clear spacing x n1 size of bar x n B WhereWhere N number of bars B width of screen chamber or channel Clear spacing and size of bars is expressed in m 17. Discuss classification of screens and state application of each class. Xiaomi Mi Mijia Laser Projector 5000 Lumens Android 6 0 Alpd 3 0 Full Hd 4k 2gb 16gb 4 Core Bluetooth Remote Projector Hd Xiaomi.

Provide net submerged area 077 m2. Footage of the screen deck. Figure is multiplied by the sq. V velocity through the screen in mps. 2.

Source: sciencedirect.com

Source: sciencedirect.com

For 6 mm bar spacing the open area is 60 3mm thick lamellas 50. Step Screens are available with either 3mm or 2mm thick movable and 3mm or 2mm fixed lamellas. Using a standard sizing formula 9 variables. Peak design wet weather flow 0631 m3s Velocity through rack at peak wet weather flow 090 ms Velocity through rack at maximum design dry weather flow 06 ms θ 65 with a mechanical cleaning device Upstream depth of. Headlosses An Overview Sciencedirect Topics.