Typical thermal incinerator design efficiencies range from 98 to 9999 and above depending on system requirements and characteristics of the contaminated stream EPA 1992. After the granular activated carbon or activated carbon fiber is filled in the tank it is adsorbed. Acid gas incinerator design.

Acid Gas Incinerator Design, These can include optional filters for particulate matter and scrubber systems for acid gases. Incinerators are typically operated between 760 and 1650C to ensure removal of COCs. Incineration like carbon adsorption is one of the best-known waste treatment methods for industrial gas. Circulating bed combustor infrared combustion rotary kiln and fluidized bed that may be applied to soil incineration.

Evaluation Of Dry Acid Gas Removal Process On Bench Scale Test Facility Coupled With Syngas Produced By O2 Co2 Blown Gasifier Sciencedirect From sciencedirect.com

Evaluation Of Dry Acid Gas Removal Process On Bench Scale Test Facility Coupled With Syngas Produced By O2 Co2 Blown Gasifier Sciencedirect From sciencedirect.com

In addition to the temperatureapplied the. VOC concentration compound type and degree of mixing EPA 1992. SRU Tail Gas Incinerators. Incineration Incinerationoperates at temperaturessuiciently high to generate the necessarycracking and oxidation reactions to convert COCs to non-toxic combustionend products.

If the shut down of compressor for very short time and the Sox emission is under control then acid gas can be flared during the acid gas compressor shut down.

Read another article:

According to the composition of acidic gas the number of impurities allowable pressure drop medium temperature operating flexibility and other conditions to make a reasonable structure design are the most basic requirements for the designer of the acidic gas burner. The second design utilizes a reagent injection system to inject the reagents directly into the combustion product gas stream either in a separate chamber or in the hot gas duct. Ensure flame contact with all gases is achieved. If the shut down of compressor for very short time and the Sox emission is under control then acid gas can be flared during the acid gas compressor shut down. The waste gas passes through an air filter to remove fine suspended particles and then enters the tank.

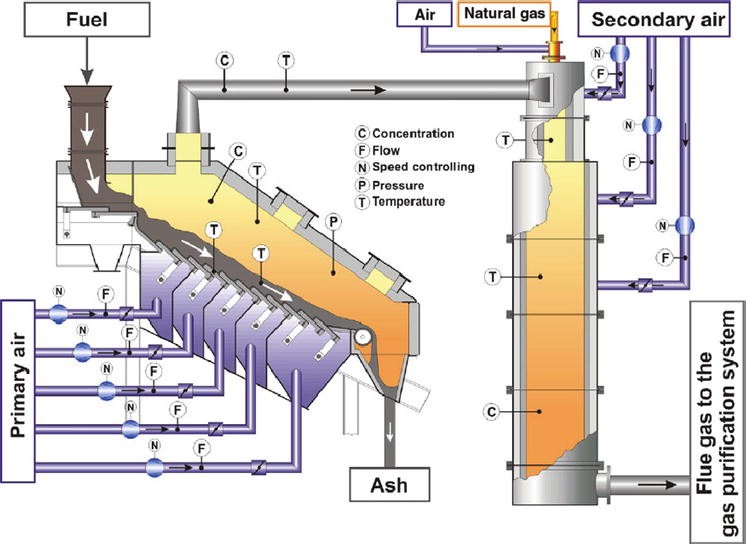

Source: gea.com

Source: gea.com

Our Incinerators are designed to reduce emissions by controlling the rate of combustion in a three chamber process and by capturing Particulate Matter in a settling chamber resulting in industry leading low emissions. The second design utilizes a reagent injection system to inject the reagents directly into the combustion product gas stream either in a separate chamber or in the hot gas duct. The following design considerations are key to Principal Technologys Tail Gas Incinerators. The advanced spin-vane assembly and burner design creates a high-intensity mixing zone while providing a stable flame. Spray Dryer Absorber.

Source: link.springer.com

Source: link.springer.com

VOC concentration compound type and degree of mixing EPA 1992. These acidic gases are converted into salts and the bleed may need to be treated. After the granular activated carbon or activated carbon fiber is filled in the tank it is adsorbed. If the shut down of compressor for very short time and the Sox emission is under control then acid gas can be flared during the acid gas compressor shut down. Martin Waste To Energy Technology Springerlink.

Source: pinterest.com

Source: pinterest.com

The design capacity of the acid gas incinerator was however later reviewed and it was decided that 2 acid gas incinerators per train instead of a single installation would improve the availability of the acid gas incinerator. The typical design conditions needed to meet 98 or. The soil or ash remaining in the incinerator after the burning. Thetreatment media with the carrier gas. Sonal Magnetics Find Address United Arab Emirates Dubai.

Source: pinterest.com

Source: pinterest.com

The design capacity of the acid gas incinerator was however later reviewed and it was decided that 2 acid gas incinerators per train instead of a single installation would improve the availability of the acid gas incinerator. Normally the incinerator are used for continous operation. The first contract for dry scrubbing on. Design principle of waste gas incinerator. Antique Warm Morning Gas Fired Incinerator X2f Heater 33195306 Gas Fires Gas Warm.

Source: malsparo.com

Source: malsparo.com

The efficiency of removal will depend on the specific equipment the chemical composition of the waste the design of the plant the chemistry of reagents and the ability of engineers to optimize these conditions which may conflict for different pollutants. The soil or ash remaining in the incinerator after the burning. PID of a dry and wet flue gas treatment system with extra bag housePDF Dry and wet scrubbing. VOC concentration compound type and degree of mixing EPA 1992. Incincerators For Medical Waste.

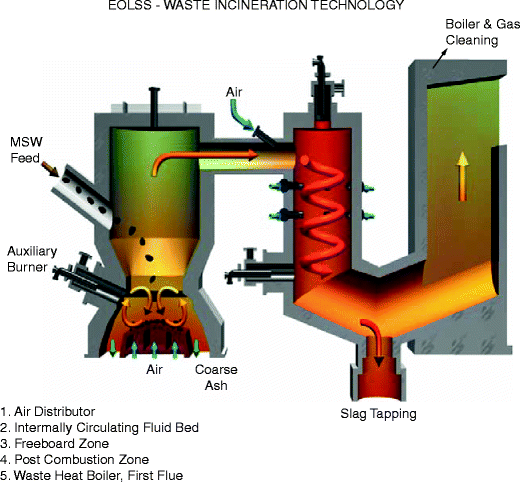

Source: link.springer.com

Source: link.springer.com

Edited by Kriss 19 June 2014 - 0712 PM. The Tricil-designed spray dryer utilizes three dual-fluid nozzles to in-ject the reagent and cool the gases from 800 to 400 F with an average outlet volume of 65000 acfm at 400F. Edited by Kriss 19 June 2014 - 0712 PM. Normally the incinerator are used for continous operation. Selection Of Incinerator Furnaces Springerlink.

Source: pinterest.com

Source: pinterest.com

The advanced spin-vane assembly and burner design creates a high-intensity mixing zone while providing a stable flame. This design provides utilization of reagents once. Ensure the oxygen content of the emitted gases is not less than 11. Typical thermal incinerator design efficiencies range from 98 to 9999 and above depending on system requirements and characteristics of the contaminated stream EPA 1992. Non Art Image Science Description Http Www Batterycouncil Org Portals 0 Images Recyclechart Gif Recycling Facts Recycling Good Environment.

Source: pinterest.com

Source: pinterest.com

The gases then flow to a pulse-jet baghouse ID fan and stack. Ensure flame contact with all gases is achieved. Edited by Kriss 19 June 2014 - 0712 PM. The structure design and the process parameters of the acid gas burner are closely connected with the heated reactor. Pin On Energia.

Source: sciencedirect.com

Source: sciencedirect.com

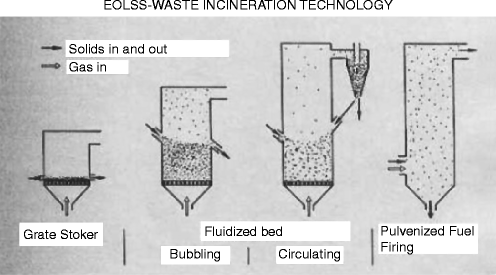

Ensure the oxygen content of the emitted gases is not less than 11. Purification and recovery method for waste gas incinerator treatment. The reagents coated on the filter bags are the only removing mechanism for. There are various types of incinerator plant designs. Emissions Sciencedirect.

Source: link.springer.com

Source: link.springer.com

Ensure the oxygen content of the emitted gases is not less than 11. Design principle of waste gas incinerator. Ensure residence time is not less than two 2 seconds. The waste gas passes through an air filter to remove fine suspended particles and then enters the tank. Selection Of Incinerator Furnaces Springerlink.

Source: mdpi.com

Source: mdpi.com

This design provides utilization of reagents once. SRU Tail Gas Incinerators. This design provides utilization of reagents once. VOC concentration compound type and degree of mixing EPA 1992. Applied Sciences Free Full Text Opportunities And Barriers For Valorizing Waste Incineration Bottom Ash Iberian Countries As A Case Study Html.

Source: pinterest.com

Source: pinterest.com

The following design considerations are key to Principal Technologys Tail Gas Incinerators. Non-VOC organic compounds are combustible and are therefore important in the design of the incinerator or oxidizer. Purification and recovery method for waste gas incinerator treatment. Thetreatment media with the carrier gas. The Mandalorian Colorful Incinerator Planner Zazzle Com Getting Organized Planner Customizable Planner.

Source: sciencedirect.com

Source: sciencedirect.com

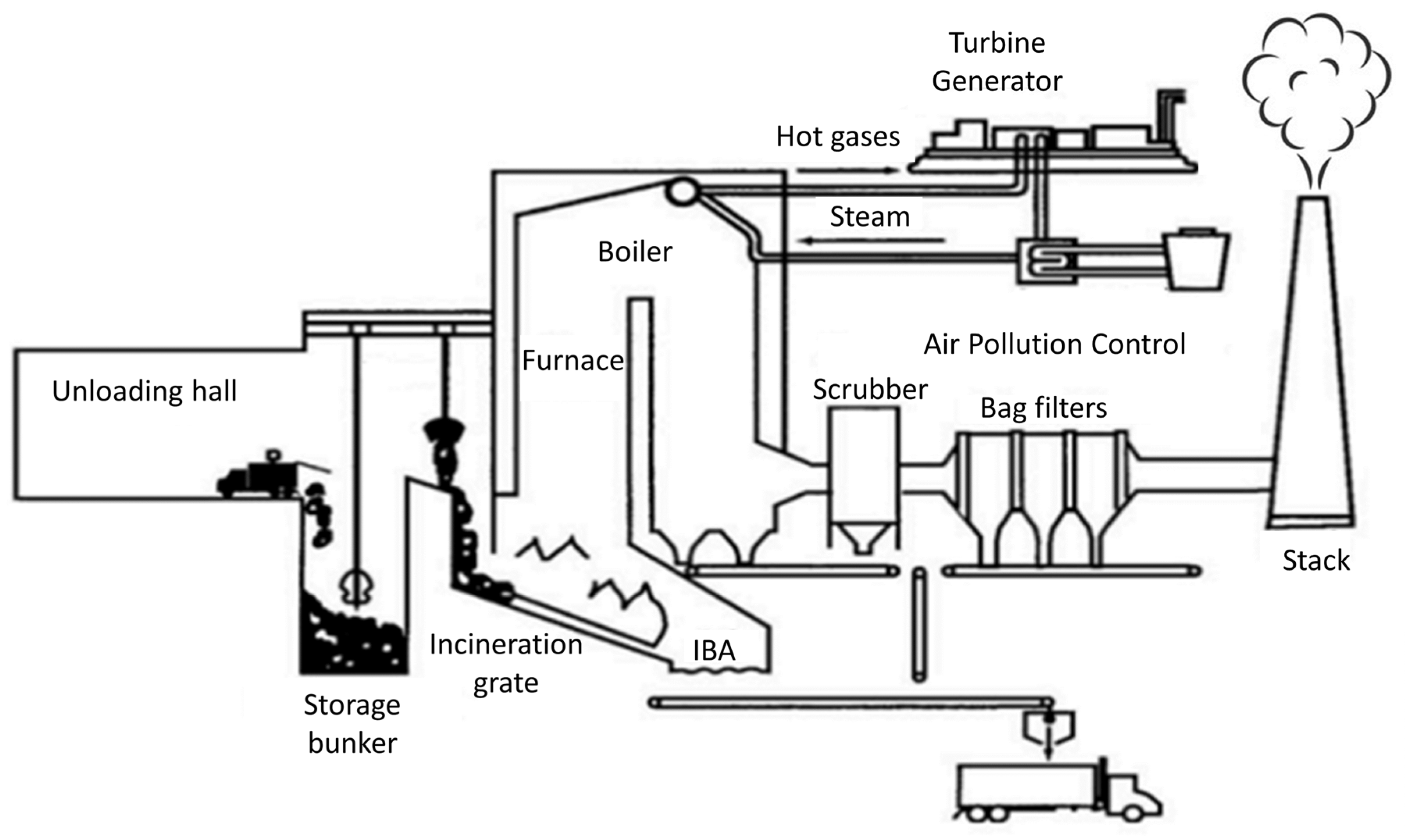

Thetreatment media with the carrier gas. The gases produced in the process must be treated to remove any remaining metal acids HCl NO x and SO x and particles of ash before they are dispersed into the atmosphere. Acid gases such as SO 2 that are not very water soluble are effectively collected in the second alkaline stage. Our proven High Intensity HI Burners are ideal for applications including acid gas reaction furnaces process heaters and boilers CO and hydrogen synthesis inert gas generation and low-NOx performance on NOxidizer systems. Chemical Solvent Process An Overview Sciencedirect Topics.

Source: pinterest.com

Source: pinterest.com

In addition to the temperatureapplied the. The gases produced in the process must be treated to remove any remaining metal acids HCl NO x and SO x and particles of ash before they are dispersed into the atmosphere. The structure design and the process parameters of the acid gas burner are closely connected with the heated reactor. The gases then flow to a pulse-jet baghouse ID fan and stack. Castable Refractory Cement 50 Lbs Woodland Direct In 2021 Pizza Oven Outdoor Plans Diy Molding Chimney Cleaning.

Source: ogj.com

Source: ogj.com

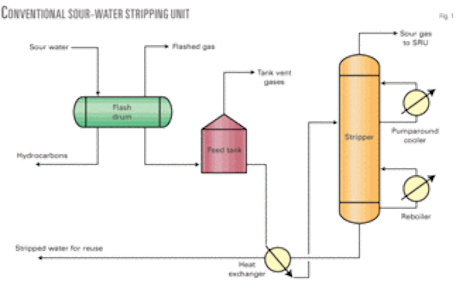

Typical thermal incinerator design efficiencies range from 98 to 9999 and above depending on system requirements and characteristics of the contaminated stream EPA 1992. The reagents coated on the filter bags are the only removing mechanism for. According to the composition of acidic gas the number of impurities allowable pressure drop medium temperature operating flexibility and other conditions to make a reasonable structure design are the most basic requirements for the designer of the acidic gas burner. Our proven High Intensity HI Burners are ideal for applications including acid gas reaction furnaces process heaters and boilers CO and hydrogen synthesis inert gas generation and low-NOx performance on NOxidizer systems. Process Developed For Enhanced H2s Recovery From Sour Water Strippers Oil Gas Journal.