Plant layout is as important a part of process plant design as it ever was but it is rarely taught as part of chemical engineering courses. Process design engineers specialist in directing and implementing capital projects for companies. A chemical engineer is designing the production process.

A Chemical Engineer Is Designing The Production Process, Chemical engineering design project PDF chemical engineering design project Muhammad Aliyu - Academiaedu Academiaedu no longer supports Internet Explorer. These include petroleum refining chemical production alternative fuels food grade products nuclear. Unfortunately not all the FEED reacts. The Chemical Engineer supports all production related activities by developing and implementing ideas that result in improved performance in.

Innovation In Chemical Engineering Aiche From aiche.org

Innovation In Chemical Engineering Aiche From aiche.org

Costellos other expertise include trouble-shooting and optimization feasibility studies computer simulations detail design construction management and startup for your chemical plant. Chemical engineers apply the principles of chemistry biology physics and math to solve problems that involve the production or use of chemicals fuel drugs food and many other products. The aim is to. Chemical Engineering plant design All engineering aspects involved in the development of a new modified or expanded commercial process in a chemical or biochemical plant.

Production engineers are a type of industrial engineer who focus on developing efficient manufacturing processes for goods such as tools and engines.

Read another article:

These include petroleum refining chemical production alternative fuels food grade products nuclear. The Conceptual Process Engineering group offers a wide Range of services in the field of conceptual development and reengineering of production processes. Also part of the FEED reacts to form BYPRODUCT instead of the desired PRODUCT. Broadly chemical engineers conceive and design processes involved in chemical manufacturing. Chemical engineers help determine how to safely use chemicals to produce or process goods and are responsible for ensuring that safety standards are in place and are followed.

Source: epicmodularprocess.com

Source: epicmodularprocess.com

The Chemical Engineer supports all production related activities by developing and implementing ideas that result in improved performance in. 12 The process requires a reactor to transform the FEED into PRODUCT Fig. The Conceptual Process Engineering group offers a wide Range of services in the field of conceptual development and reengineering of production processes. The aim is to. What Is A Process Engineer Facts About Process Engineering And Design.

Source: sciencedirect.com

Source: sciencedirect.com

As part of a team with other technical units. They are most often employed by large-scale manufacturing plants to maximize productivity and product. Chemical engineers apply the principles of chemistry biology physics and math to solve problems that involve the production or use of chemicals fuel drugs food and many other products. Process engineers on the other hand often use chemistry principles to design new processes or production methods for goods and materials. Engineering Design An Overview Sciencedirect Topics.

Source: sciencedirect.com

Source: sciencedirect.com

Process engineers on the other hand often use chemistry principles to design new processes or production methods for goods and materials. A attor Figure 12 Process design starts with the reactor. The Conceptual Process Engineering group offers a wide Range of services in the field of conceptual development and reengineering of production processes. The main role of chemical engineers is to design and troubleshoot processes for the production of chemicals fuels foods pharmaceuticals and biologicals to name just a few. Design Process An Overview Sciencedirect Topics.

Source: sciencedirect.com

Source: sciencedirect.com

Any chemical engineer can design some large-scale process converting raw materials chemicals living cells energy and microorganisms into some useful products and forms being involved in many aspects of plant operations and design including safety and hazard assessments process analysis and design chemical reaction engineering control. Chemical engineering community traditionally responsible for process development and manufacturing Left product designdevelopment to the chemists who threw product over the wall Chemical engineers tracked product purity and. Chemical engineering design project PDF chemical engineering design project Muhammad Aliyu - Academiaedu Academiaedu no longer supports Internet Explorer. The process-design-basis document represents the owners instructions to the design engineering organization about what the owner wants designed and how the owner wants the. Systematic Design An Overview Sciencedirect Topics.

Whereas chemical process design engineer mostly deals with the new processesnew projects which is on paper only. The aim is to. Chemical engineer will make economic evaluation of process Design each individual piece of equipment Develops plant layout Provides guidance for the plant control and operation. As a chemical process engineering company we provide design applied chemical engineering and safety services to a wide range of process industries. 2.

Source: engineeringproductdesign.com

Source: engineeringproductdesign.com

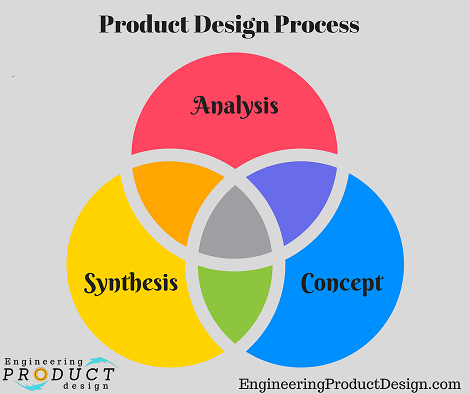

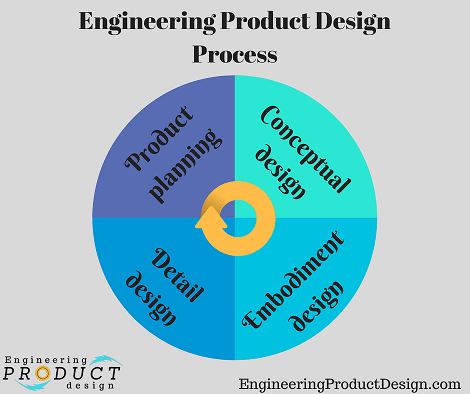

They design processes and equipment for large-scale manufacturing plan and test production methods and byproducts treatment and direct facility operations. Chemical engineer will make economic evaluation of process Design each individual piece of equipment Develops plant layout Provides guidance for the plant control and operation. Chemical engineering community traditionally responsible for process development and manufacturing Left product designdevelopment to the chemists who threw product over the wall Chemical engineers tracked product purity and. Whereas chemical process design engineer mostly deals with the new processesnew projects which is on paper only. Product Design Process Engineering Product Design.

Source: twi-global.com

Source: twi-global.com

Chemical engineers apply the principles of chemistry biology physics and math to solve problems that involve the production or use of chemicals fuel drugs food and many other products. The process-design-basis document represents the owners instructions to the design engineering organization about what the owner wants designed and how the owner wants the. Production engineers are a type of industrial engineer who focus on developing efficient manufacturing processes for goods such as tools and engines. While process plant layout is a critical aspect of chemical process industries CPI operations the majority of the seminal works in this area have been published in trade journals 110 or classic. What Is The Engineering Design Process A Complete Guide Twi.

Source: teachengineering.org

Source: teachengineering.org

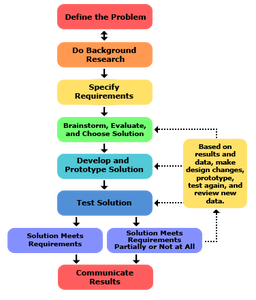

There are many places where I share my knowledge and expertise about chemical process engineering and plant design. For example the ThermoData Engine TDE developed at NIST is incorporated into a chemical simulator produced by AspenTech that is used by hundreds of thousands of chemical plant engineers and designers. The Chemical Engineer supports all production related activities by developing and implementing ideas that result in improved performance in. As part of a team with other technical units. Design Step 1 Identify The Need Activity Teachengineering.

Source: sciencedirect.com

Source: sciencedirect.com

12 Overall Process Design Consider the process illustrated in Fig. Chemical engineer will make economic evaluation of process Design each individual piece of equipment Develops plant layout Provides guidance for the plant control and operation. Broadly chemical engineers conceive and design processes involved in chemical manufacturing. 12 Overall Process Design Consider the process illustrated in Fig. Engineering Design An Overview Sciencedirect Topics.

Source: instructables.com

Source: instructables.com

CHEMICAL PROCESS ENGINEERING AND PLANT DESIGN CONTENT. The Chemical Engineer supports all production related activities by developing and implementing ideas that result in improved performance in. It is a part of engineering which deals with the production of chemicals and other products using the raw materials that require chemical processing. Chemical Engineering plant design All engineering aspects involved in the development of a new modified or expanded commercial process in a chemical or biochemical plant. What Is The Engineering Design Process 8 Steps Instructables.

Source: researchgate.net

Source: researchgate.net

Our team of seasoned Process Design Engineers customize front-end engineering packages FEED for bench scale pilot plant full scale chemical plants. CHEMICAL PROCESS ENGINEERING AND PLANT DESIGN CONTENT. When there are specific issues with the method of production thats in place they will assess the issues and determine how to resolve them by changing production strategies by. Any chemical engineer can design some large-scale process converting raw materials chemicals living cells energy and microorganisms into some useful products and forms being involved in many aspects of plant operations and design including safety and hazard assessments process analysis and design chemical reaction engineering control. Pdf How Innovative Design Can Contribute To Chemical And Process Engineering Development Opening New Innovation Paths By Applying The C K Method.

Source: sciencedirect.com

Source: sciencedirect.com

Chemical engineer will make economic evaluation of process Design each individual piece of equipment Develops plant layout Provides guidance for the plant control and operation. 12 Overall Process Design Consider the process illustrated in Fig. Chemical engineers apply the principles of chemistry biology physics and math to solve problems that involve the production or use of chemicals fuel drugs food and many other products. In this unit youll perform design work on a large-scale process plant. Design Decision Making An Overview Sciencedirect Topics.

Source: engineeringproductdesign.com

Source: engineeringproductdesign.com

As a chemical process engineering company we provide design applied chemical engineering and safety services to a wide range of process industries. For example the ThermoData Engine TDE developed at NIST is incorporated into a chemical simulator produced by AspenTech that is used by hundreds of thousands of chemical plant engineers and designers. Most of them are for free. 12 Overall Process Design Consider the process illustrated in Fig. Product Design Process Engineering Product Design.

Source: aiche.org

Source: aiche.org

In this unit youll perform design work on a large-scale process plant. Process design engineers specialist in directing and implementing capital projects for companies. They design processes and equipment for large-scale manufacturing plan and test production methods and byproducts treatment and direct facility operations. There are many places where I share my knowledge and expertise about chemical process engineering and plant design. Innovation In Chemical Engineering Aiche.

Costellos other expertise include trouble-shooting and optimization feasibility studies computer simulations detail design construction management and startup for your chemical plant. Our team of seasoned Process Design Engineers customize front-end engineering packages FEED for bench scale pilot plant full scale chemical plants. For nearly 100 years NIST has provided the chemical industry with the reliable data it needs to design new chemical products and manufacturing processes. Any chemical engineer can design some large-scale process converting raw materials chemicals living cells energy and microorganisms into some useful products and forms being involved in many aspects of plant operations and design including safety and hazard assessments process analysis and design chemical reaction engineering control. What Are The 8 Steps Of The Engineering Design Process Quora.